Subsequently, the growth process leads to a change in the mechanical behaviour, which usually has a large influence on the performance of the given implant. It is important to notice that since the model presented in this paper is a purely phenomenological approach, we disregard the micromechanical effects of remodelling in the following and concentrate exclusively on the description of volumetric growth. From a physiological point of view this process, which we will call growth in the following, is mainly driven by a change in mass and internal structure of the given biological material. a certain critical stress state is neither exceeded nor fallen below. The goal of this process is to reach a homeostatic state in which e.g.

Early works in the field of biomechanics have already pointed out that biological tissues adapt dynamically to the environment they are exposed to (see e.g. Designing and constructing highly complex medical implants is a big challenge due to the biomechanical properties of the underlying cultivated tissue. Great progress has been made in implant research in particular, with the cultivation of biohybrid heart valves being just one example among many (Fioretta et al. The production and use of artificially grown biological tissue has become an important research topic in the medical context over the last two decades. Besides the theoretical development, we also describe the algorithmic implementation and furthermore compare the newly derived model with a standard formulation of isotropic growth. It furthermore allows the model to flexibly adapt to changing boundary and loading conditions. This approach naturally leads to a formulation that is able to cover both, isotropic and anisotropic growth-related changes in geometry. Making use of well-established methods from visco-plasticity, the evolution of the growth-related right Cauchy–Green tensor is subsequently defined as a time-dependent associative evolution law with respect to the introduced potential. Such a potential describes all eligible homeostatic stress states that can ultimately be reached as a result of the growth process. Instead of using the standard approach of a-priori defining the structure of the growth tensor, we postulate the existence of a general growth potential. Within this contribution, we propose a new macroscopic approach for modelling stress-driven volumetric growth occurring in soft tissues.

Feap to gmsh how to#

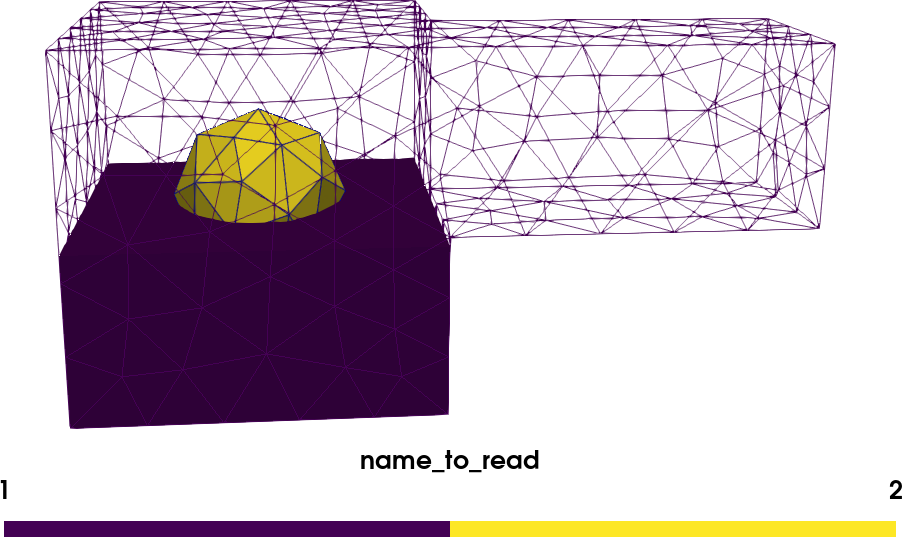

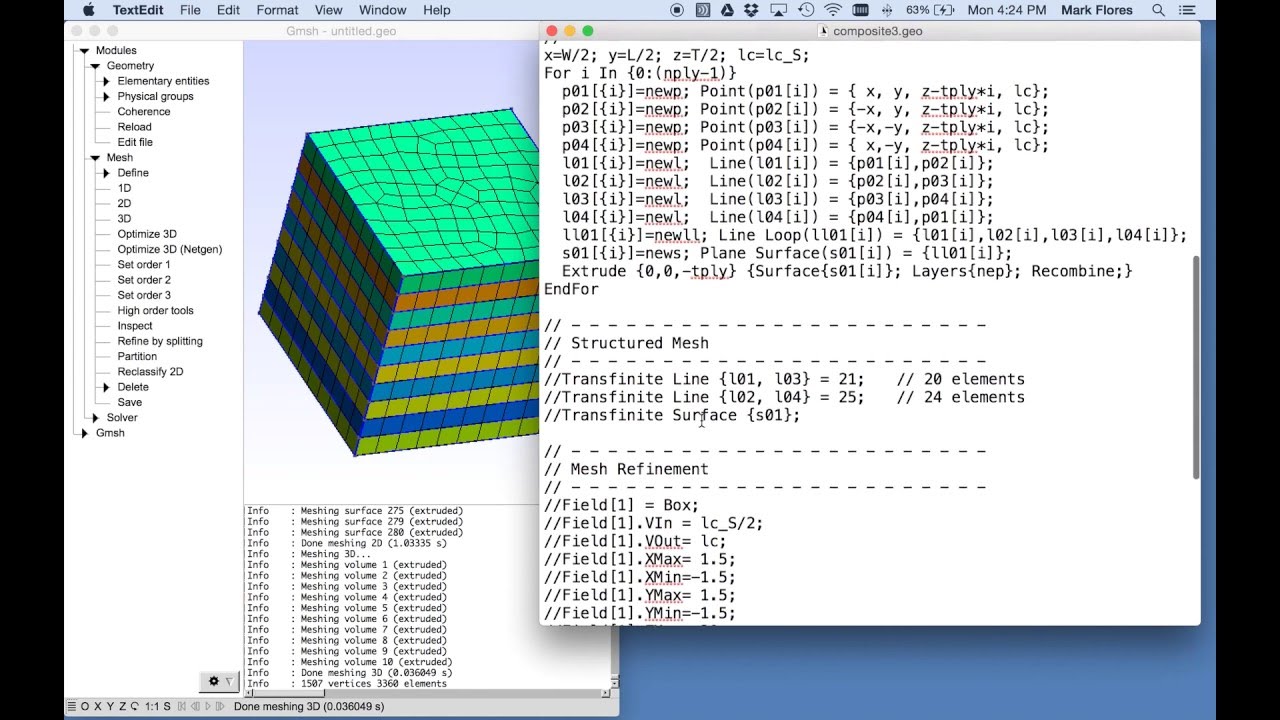

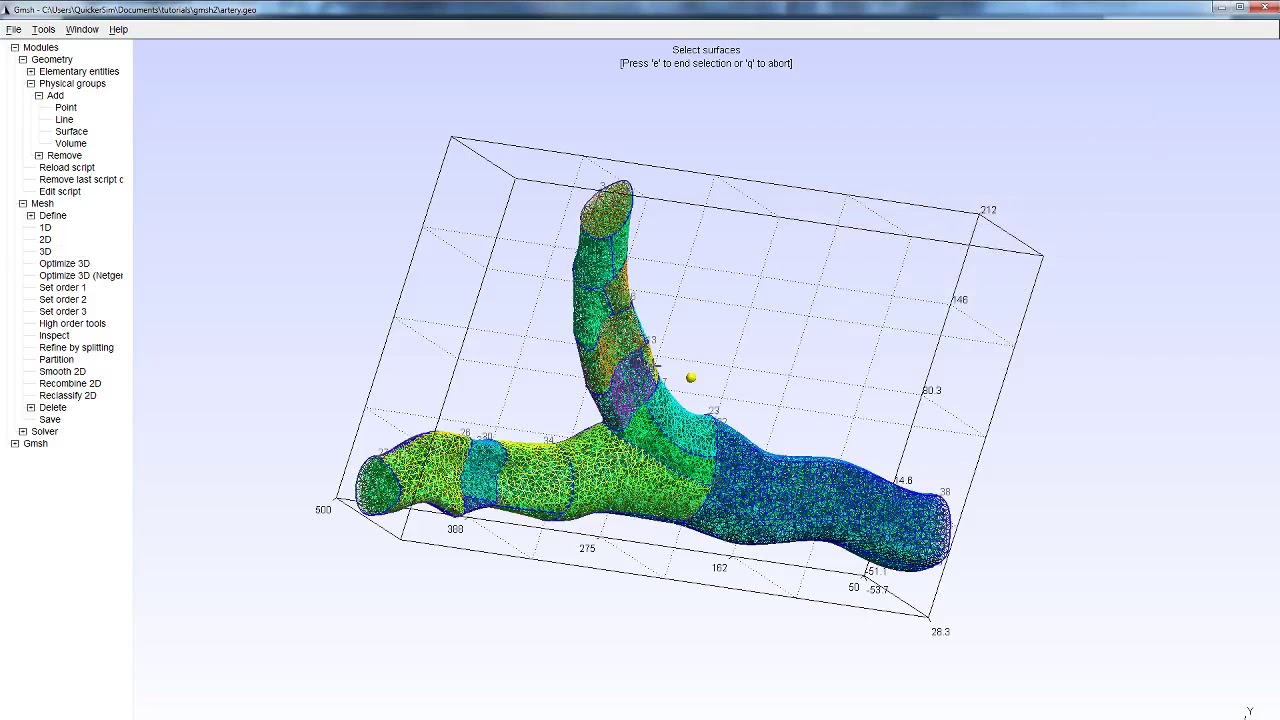

I don't have an exact picture of how to get this all to work.The simulation of growth processes within soft biological tissues is of utmost importance for many applications in the medical sector. The sign of the surface seems to depend on whether the node ordering on the surface is clockwise or counter-clockwise with respect to the volume being created. That means that the normal direction of each surface has to be tracked when building a volume. When building surfaces in Gmsh, it appears that surfaces for a volume must all be assigned the proper direction. It appears that regions are differentiated by selecting a point in each of the partitions and marking the appropriate attribute: Reading the Tetgen documentation, it appears that surfaces are made of facets which surround a volume It doesn't appear that Tetgen requires the nodes of a facet to be ordered in any specific direction. The meshing tool would then mesh each of the closed volumes, and ensure that nodes and triangles on common surfaces are shared. Volumes would then be created by exporting the surface information to the meshing tool. In order for my simulations to work, the nodes and triangles must be coincident on volumes that share a surface.Īs a result of a boolean operation in Freecad, a duplicate face appears in each volume, and this results in a non-conforming mesh.Īs input for a meshing tool, I foresee using the python interface to iterate over all surfaces in the structure and identifying duplicates.

My understanding is that 3d meshing tools will mesh volumes of closed surfaces. Since the semiconductor and insulating regions have different material properties, the mesh has to be partitioned accordingly. For example, metal, insulators, and semiconductor materials. I want to solve these quantities in 3d on devices with many regions of different materials. This is exactly what I am trying to solve. Simulation of electric fields, current densities, densities of charge carriers and their recombination, heat generation and conduction.

Bernd wrote:What is a semiconductor simulation.I guess, that means simulating operation of a transistor, for example.

0 kommentar(er)

0 kommentar(er)